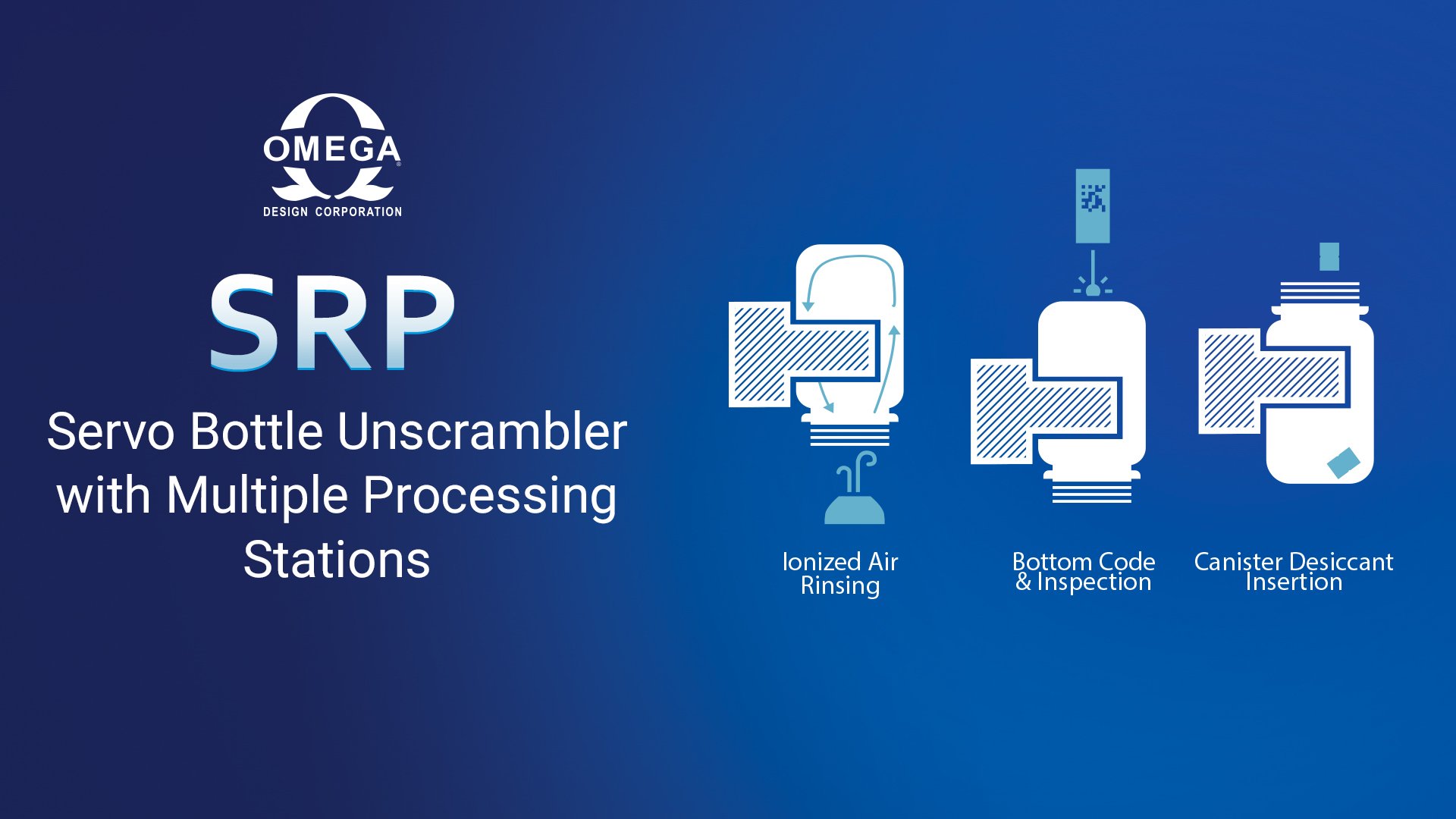

Highlights

Pick and Place Precision: Integrated vision system with multi-axis robot places bottles onto a conveyor or into stabilizing pucks

Complex Bottle Shapes: Ideal for Personal Care Products, Consumer Goods and tottles

Compact Footprint: Integrated Hopper and electrical enclosure; Fully enclosed system; Significantly smaller footprint than comparable solutions

Advanced Controls: 15” HMI touch screen on a pivoting mount arm; GuardLogix PLC with I/O link devices

More Robots; More Speed: Configure with multiple robots to meet speed capacity

Limited Changeover Points: Greatly reducing setup times

Easy to Maintain: Less maintenance & fewer wear parts than traditional mechanical sorting

Downloads

Robotic Bottle Unscrambler

Advanced Container Handling for COmplex Bottle Lines

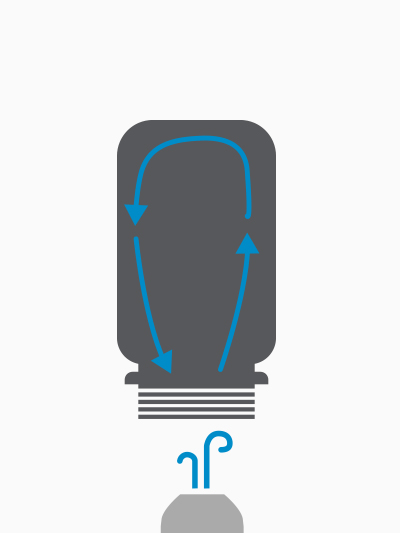

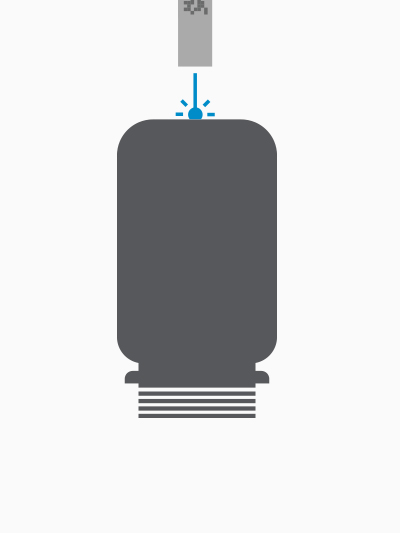

This fully automatic system features a parallel-kinematic, multi-axis robot to separate, orient and position bottles onto a discharge conveyor or into stabilizing pucks.

An integrated Hopper system delivers bottles to a Lane Diverter, where bottles get presented onto two infeed Vacuum Conveyors. A parallel kinematic multi-axis robot with vacuum cupped end effector picks a bottle and orients it upright onto a discharge conveyor or into stabilizing pucks. An overhead vision system transmits bottle information to optimize robot motion.